Tank Mixing Eductors

Tank Mixing Eductors

Tank Eductors (also referred to as circulating tank eductors & tank liquid agitators) provide an effective way to mix liquids in open or enclosed tanks. They produce an intimate mixing action between the components of a liquid, while keeping the contents of the tank in constant motion. In many cases they produce a mixing action that cannot be duplicated using mechanical methods. Tank eductors can handle a variety of viscosities and types of liquids, including slurries and suspensions. Their thorough mixing action makes them especially useful for maintaining uniform liquid characteristics throughout the tank contents , such as temperature, pH, or solids distribution. The tank eductor is also used to prevent separation of non-mixable liquids or stratification of liquids having different specific gravities. Tank eductors offer low initial cost, light weight and easy installation. They are inherently non-clogging and with no moving parts, require little or no maintenance . Tank eductors allow the use of a smaller recirculating pump than normally would be needed to move a given volume of liquid. This saves energy while providing more effective mixing and circulation. They are available in materials to suit a variety of applications in food, chemical, refining and other process industries.

How tank mixing eductors work

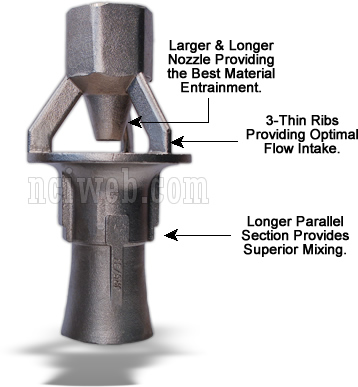

A predetermined amount of liquid (called operating fluid) is pumped through a header to one or more tank eductors submerged inside the tank. Depending upon the application , the operating fluid can be liquid drawn from the tank, or it can be a second liquid from another source that is to be mixed with the tank contents. As the operating fluid leaves the nozzle of the tank eductor, it entrains material from the tank. The operating fluid and entrained material are thoroughly mixed inside the parallel section of the tank eductor before being discharged. The discharge flow, or plume, continues the mixing and agitation o f the liquid throughout the tank.

Tank Eductor Features:

Standard features and available options

- Optimized flow paths enable the tank eductor to maintain a high "entrainment ratio" (the ratio of fluid sucked into the motive fluid) while maximizing the hydraulic efficiency (the ratio of hydraulic power at the outlet of the tank eductor to the hydraulic power at the inlet) to generate an optimum flow field from the greatest flow amplification.

No moving parts in the eductor, minimizing maintenance expenses.

No moving parts in the eductor, minimizing maintenance expenses.

Optimum flow field enables more activity within the tank than competitive units without changing pumps.- Compact design and ease of mounting keeps the tank eductor from interfering with other tank equipment.

- "In-tank" mounting eliminates need for costly, complex mounting structures above tanks.

- Tank eductors can be used in a wide variety of open vessels or closed tanks.

Eliminates stratification and promotes a homogeneous tank with relation to pH, temperature, solids or gas dispersion, and distribution of chemicals.

A predetermined amount of liquid (called operating fluid) is pumped through a header to one or more tank eductors submerged inside the tank. Depending upon the application , the operating fluid can be liquid drawn from the tank, or it can be a second liquid from another source that is to be mixed with the tank contents . As the operating fluid leaves the nozzle of the tank eductor, it entrains material from the tank. The operating fluid and entrained material are thoroughly mixed inside the parallel section of the tank eductor before being discharged . The discharge flow, or plume, continues the mixing and agitation o f the liquid throughout the tank.

Edathon Coating Option

- Excellent Corrosion Resistance

Excellent Abrasion Resistance

300° F Continuous Service

Good Non-Stick Characteristics - Excellent Dielectric Insulation

Radiation Resistant

This coating is applied via electrostatic powder spray or fluidized powder bed. In addition to possessing the high chemical and temperature resistance which all fluoropolymers are noted for, Edathon's strengths, radiation resistance, wear resistance, and creep resistance are significantly greater than those of other fluoropolymers such as PTFE, FEP, or PFA.

ULTRATUF Coating Option

ULTRATUF Coating Option

Fusion Bonded Coating

- Machinable

- Excellent Abrasion Resistance

- 300° F Continuous Service

- Self-Lubricating

- Electrically Insulating

- Impact Resistant

- Withstands Saltwater Environment

At last, a single coating offering abrasion resistance so excellent that it can withstand the punishment of sand blasting and yet be used on medical instruments subjected to repeated sterilization. This unique coating can be applied from 5-35 mils thick and has found many areas of use.

Standard materials TLA's are cast or fabricated in: bronze, 316 stainless and carbon steel. Cast units range from IPS 3/4 to 2. Larger sizes and other materials are fabricated. Consult the factory for details.

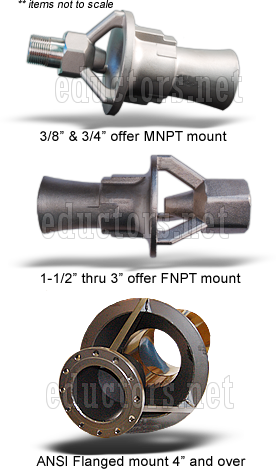

Standard body connection for 3/8 and 3/4 units is male NPT and for 1-1/2 through 3, female NPT. Over 4" is flanged. Optional connections include female/male NPT, butt weld, socket weld, VictualicTm, sil-braze, and flanged.

Standard Materials:

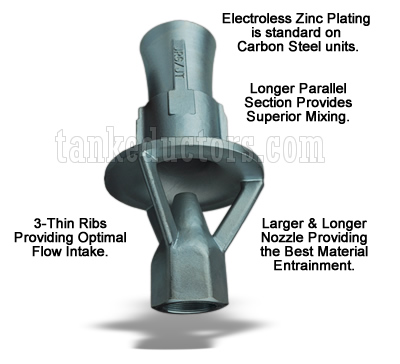

* Carbon Steel (Electroless Zinc Plating is now a standard on Carbon Steel units. This results in improved corrosion inhibition, improved wearability and reduces flow friction.)

* 316SS

* Bronze

* PVC

* PPL

* PVDF

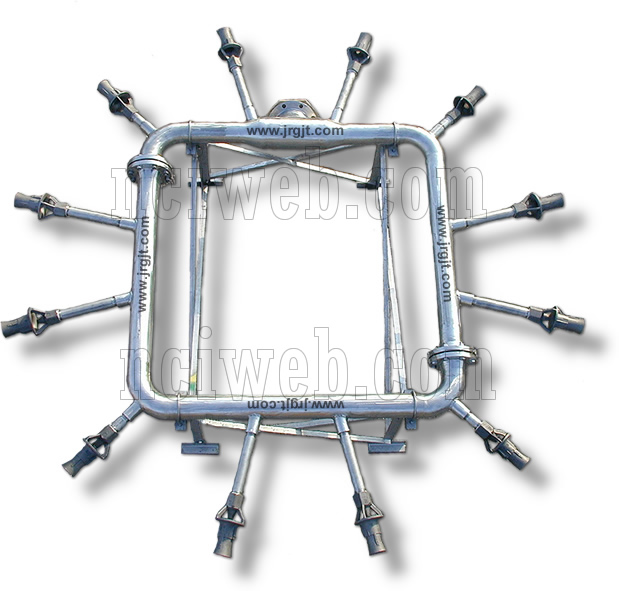

Custom Tank Eductor Manifold Designs

We can design manifolds customized to your unique application(s). Drawing from our years of experience will help take the guess work out of your layout design(s).

Calculating Turnover Rates

When turnover rates are used to calculate mixing it is important to consider the viscosity of the fluid and the amounts of solids present. It also important to consider the size, weight and shape of the tanks which may limit the free flow of the mixing solids to maintain suspension. The viscosity or odd flow field within the tank, and suspensions that separate easily may demand constant mixing. In most cases, the tank eductor will usually provide a homogeneous mixture of the vessel in one to three turnovers.

When operated with pressure drops between 10 and 60 PSI, the tank eductor will entrain at least 4 times as much tank liquid as the motive liquid used. For pressure drops over 60 PSI, the amount of fluid entrained by the tank eductor remains almost constant. Up to 5 to 1 Entrainment.

To calculate the required turnover time for the tank with pressure drops between 10 and 60 PSI, divide the tank volume by the result of the number of eductors times the outlet flow (GPM).

| Size IPS | Pressure Difference, PSI | ||||||||||||

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 140 | ||

| Motive Flow (GPM) | 7.1 | 10.0 | 12.3 | 14.2 | 15.8 | 17.4 | 18.7 | 20.1 | 21.3 | 22.4 | 24.6 | 26.5 | |

| 3/8" mnpt | Outlet Flow (GPM) | 35 | 50 | 61 | 71 | 79 | 87 | 88 | 90 | 91 | 92 | 94 | 96 |

| Max. Plume Length | 4 | 8 | 12 | 16 | 22 | 29 | 36 | 43 | 50 | 58 | 72 | 86 | |

| 3/4" mnpt | Motive Flow (GPM) | 15.4 | 21.8 | 26.7 | 30.8 | 34.5 | 37.8 | 40.8 | 43.6 | 46.3 | 48.8 | 53.4 | 57.7 |

| Outlet Flow (GPM) | 77 | 109 | 134 | 154 | 172 | 189 | 192 | 195 | 197 | 200 | 204 | 209 | |

| Max. Plume Length (FT) | 5 | 11 | 17 | 24 | 33 | 42 | 53 | 64 | 74 | 85 | 106 | 127 | |

| Motive Flow (GPM) | 30.8 | 43.6 | 53.4 | 61.6 | 68.9 | 75.5 | 81.5 | 87.2 | 92.5 | 97.5 | 107 | 115 | |

| 1-1/2" fnpt | Outlet Flow (GPM) | 154 | 218 | 267 | 306 | 345 | 378 | 384 | 389 | 395 | 400 | 409 | 417 |

| Max. Plume Length (FT) | 7.5 | 16 | 24 | 34 | 46 | 60 | 75 | 90 | 105 | 120 | 150 | 180 | |

| 2" fnpt | Motive Flow (GPM) | 61.6 | 87.2 | 107 | 123 | 138 | 151 | 163 | 174 | 185 | 195 | 214 | 231 |

| Outlet Flow (GPM) | 308 | 436 | 534 | 616 | 689 | 755 | 767 | 778 | 789 | 799 | 818 | 835 | |

| Max. Plume Length (FT) | 11 | 23 | 34 | 48 | 65 | 85 | 106 | 127 | 148 | 170 | 212 | 255 | |

| Motive Flow (GPM) | 142 | 201 | 246 | 283 | 317 | 347 | 375 | 401 | 426 | 449 | 491 | 531 | |

| 3" fnpt | Outlet Flow (GPM) | 708 | 1,003 | 1,228 | 1,417 | 1,585 | 1,737 | 1,764 | 1,790 | 1,815 | 1,836 | 1,880 | 1,920 |

| Max. Plume Length (FT) | 16 | 34 | 51 | 73 | 99 | 129 | 161 | 193 | 225 | 257 | 322 | 386 | |

| 4" flg | Motive Flow (GPM) | 246 | 349 | 427 | 493 | 551 | 604 | 652 | 698 | 740 | 780 | 856 | 920 |

| Outlet Flow (GPM) | 1232 | 1744 | 2136 | 2448 | 2760 | 3024 | 3072 | 3112 | 3160 | 3200 | 3272 | 3336 | |

| Max. Plume Length (FT) | 22 | 41 | 60 | 95 | 132 | 164 | 196 | 228 | 260 | 295 | 360 | 424 | |

| 6" flg | Motive Flow (GPM) | 493 | 698 | 854 | 986 | 1102 | 1208 | 1304 | 1395 | 1480 | 1560 | 1712 | 1840 |

| Outlet Flow (GPM) | 2464 | 3488 | 4272 | 4896 | 5520 | 6048 | 6144 | 6224 | 6320 | 6400 | 6544 | 6672 | |

| 8" flg | Motive Flow (GPM) | 986 | 1395 | 1709 | 1971 | 2205 | 2416 | 2608 | 2790 | 2960 | 3120 | 3424 | 3680 |

| Outlet Flow (GPM) (FT) | 4928 | 6976 | 8544 | 9792 | 11040 | 12096 | 12384 | 12448 | 12640 | 12800 | 13088 | 13344 | |

| 10" flg | Motive Flow (GPM) | 1971 | 2790 | 3418 | 3942 | 4410 | 4832 | 5216 | 5581 | 5920 | 6240 | 6848 | 7360 |

| Outlet Flow (GPM) | 9856 | 13952 | 17088 | 19584 | 22080 | 24192 | 24576 | 24896 | 25344 | 25600 | 26176 | 26688 | |

|

| Size | Max Free Passage | Dimension A | Dimension B | Dimension C | Dimension D | ||||

| IN | (mm) | IN | (mm) | IPS | (mm) | IN | (mm) | ||

| 3/8" | 0.2656 | 5.00 | (127) | 2.50 | (64) | 3/8 MNPT | (10) | .50 | (12) |

| 3/4" | 0.4062 | 7.25 | (184) | 3.69 | (94) | 3/4 MNPT | (20) | .81 | (20) |

| 1-1/2" | 0.5625 | 10.88 | (276) | 5.50 | (140) | 1-1/2 FNPT | (40) | 1.12 | (28) |

| 2" | 0.8125 | 14.50 | (368) | 7.69 | (195) | 2 FNPT | (50) | 1.62 | (41) |

| 3" | 1.1875 | 22.00 | (559) | 11.75 | (298) | 3 FNPT | (80) | 2.50 | (63) |

| 4" | consult | 25.00 | (635) | 12.00 | (305) | 4 FLGD | (100) | 3.00 | (76) |

| 6" | consult | 35.00 | (889) | 25.00 | (635) | 6 FLGD | (150) | 4.50 | (114) |

| 8" | consult | Contact Us for 8" and Over | |||||||

Jet Pump Navigation

Pressure Ratings

While our competition design their eductors for nominal pressure ratings, NCI Eductors are designed and produced to meet rigorous ASME/ANSI specifications.

Our eductors and jet pumps offer ratings about 30% higher than most competitors.

NCI Eductors are rated at 316SS: 720 psig @ 100 F | Carbon Steel: 740 psig @ 100 F | Bronze: 500 psig @ 100 F