Eductors for Heating Liquids

Eductor liquid heaters operate by condensing steam into the liquid that is being heated. The process ensures a complete transfer of the BTUs in the steam to the liquid. The steam gives up its BTUs as it condenses into the liquid. This also dilutes the motive liquid with the condensate. Eductor liquid heaters function under the normal principles of eductors. In actuality, the process is that of a liquid pumping a gas.

Eductor liquid heaters operate by condensing steam into the liquid that is being heated. The process ensures a complete transfer of the BTUs in the steam to the liquid. The steam gives up its BTUs as it condenses into the liquid. This also dilutes the motive liquid with the condensate. Eductor liquid heaters function under the normal principles of eductors. In actuality, the process is that of a liquid pumping a gas.

The only thing that differs with pumping steam as a suction fluid is the increased affinity of steam for cold water. Because of this affinity, a greater volume of steam is pumped under the same conditions. Also, in some cases, the BTUs being released allow the unit to discharge to higher pressures than either the motive or the suction pressure.

Eductors Specifications

Eductor liquid heaters have three service connections that will affect the performance of the units. The actual conditions at these connections should be clearly specified to ensure correct operation. The motive is the connection where the liquid to be heated enters the eductor. The heating (steam) is the connection where the steam enters the eductor. The discharge connection is where the heated fluid exits the eductor.

Where can Liquid Heating Eductors be Used?

Eductors have been used to successfully heat liquids in many industries and processes. The units can heat in-line or in-tank to achieve results that will improve your process. These units are used in the following industries: Pulp and Paper, Chemical, Petroleum, Dairy, Agriculture, and Breweries. Typical applications include: sterilization, cooking, heated wash down sprays, heating solutions, pasteurization in-line, mixing while heating, activating temperature controlled substances, and maintenance of tempering vessels.

Motive Connection: At this connection, the liquid to be heated enters the eductor. In most instances, the liquid is under pressure at this point. As it . passes through the nozzle, the pressure is converted to a high velocity stream that passes into the heating chamber. The velocity of the motive liquid in the heating chamber allows the steam to be drawn into the liquid to be heated.

Heating (Steam) Connection: The entrainment of steam into the liquid begins as the high velocity liquid stream draws the gas (steam) into the heating chamber as it passes through the chamber. This lowers the pressure in the heating chamber, allowing more steam to be pushed into this area. As the steam is entrained into the high velocity liquid, its BTUs are released into the fluid, heating the liquid. The resulting mixture is pushed by momentum toward the outlet connection of the eductor.

Discharge Connection: As the condensed steam and liquid mixture go through the eductor, the energies of the two fluids are combined. This combination and the relative percentage of each fluid will have a great effect on the amount of pressure that can be recovered at the outlet of the eductor. Unlike other eductor applications, the heater generally has a positive power input on both incoming ports. In the case of the liquid motive, this power is from the pressure of the incoming liquid. In the case of the heating steam, this power can come from the pressure of the incoming steam and/or from the internal energy of the steam being released as it condenses. The percentage of each fluid entering the eductor and how both are mixed will determine how much back pressure can be tolerated. In the event of high discharge pressures, the eductor must be started and reach a state of equilibrium before the maximum discharge pressure can be handled. In most cases, this requires the installation of a bypass valve for start up.

| Model | MLE | MLH | ULJ |

|---|---|---|---|

| Heating Process | In-line | In-line | In-line |

| Max Temp Rise (°F) | 180 | 215 | 200 |

| Maximum Flow Heated (GPM) | 5000 | 5000 | 700 |

| Steam Press Range (PSIG) | Vac-45 | Vac-120 | 0-150 |

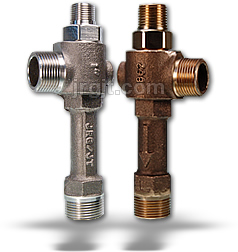

Typical Liquid Eductor Heater Units

We offer several types of liquid heating eductors that are designed to heat over a variety of conditions. Because of the diversity of applications for the units, the motive and heating ports may be in different locations. It is important for proper operation of the units that the liquid and steam be connected to the proper ports. The following models of eductors can be used in heating applications: UU, MLE, and MLH. On all of these units the liquid to be heated enters the motive connection.

Why are eductors chosen for HEATING applications ?

Small physical size - Heating done completely within piping systems.

Low cost of installation - Foundations and wiring are not required.

Integral Gage Ports - Enables rapid troubleshooting.

No moving parts - Reduced maintenance.

ASME/ANSI B16.5 Rating - Enables ANSI rating of entire systems.

No packing glands - Reduced maintenance.

Lubrication is not required - Reduced maintenance.

Body as strong as piping - Handles normal piping stresses.

Wide variety of connection types available - Male/Female NPT, Butt/Socket Weld, Flanged, Silbraze, Victaulic

Properly installed eductors require few shutdown procedures - Ease of control for intermittent operations

Hex mounting on body - Easy mounting to piping.

Low relative cost for exotic materials - The no moving parts feature makes it easy and quick to obtain exotic materials. These materials will not affect the performance of the units.

Longer service life - The lack of moving parts means many units will operate for years without affecting performance.

O-Ring sealed body/nozzle joint - Bubble tight seal, easy effective maintenance.

Use of sources normally considered waste - In many cases, steam can be used for heating with pressures as low as 1 or 2 PSIG. This allows you to gain value from a resource normally vented or returned to your boiler.

Smooth body flow passages - High efficiency and flows.

Economical use of waste steam - Low pressure steam still contains substantial heating value, all of which is used.

How to Use Eductors for Heating in Process Lines Using Liquid as the Motivating Stream

The following models of eductors can be used as heating devices using pressurized liquid as the motive force for the process: MLH, MLE, ULJ. These units operate over a variety of conditions.

The models MLE and MLH will pull more steam for a given set of pressure conditions. They require a larger pressure drop through the eductor, but it results in a higher temperature rise through the eductor per pass. These units are generally used when the system requires a single pass through the eductor. If they are operated intermittently, the pressure drop will increase when the steam is shut off. When using low pressure steam for heating, it is recommended that the motive liquid temperature in these units not exceed 100°F. Higher incoming temperatures should be thoroughly evaluated to avoid objectionable noise and water hammer. To determine the actual operating parameters of each unit, refer to the performance table for that unit.

The model ULJ generally requires a steam pressure greater than the liquid pressure being used. It also produces less pressure

drop on the liquid, but there is a lower temperature rise for the liquid medium, as the lower steam flows contain less total BTUs. These models are designed so that they can be used on a multiple pass system. Many times these units are used to heat jackets on reactors or other systems where low pressure drops in the liquid lines are required or where a small temperature increase per pass is required. The lower amount of steam injected per pass allows these units to heat to higher final temperatures. Also, the liquid pressure drop remains small in these units when the steam flow is shut off.

The units, listed in general order of largest to smallest temperature rise and pressure drop, are: MLE, MLH, ULJ. These units are available for use to heat in-line, producing hot liquids for spray cleaning operations, heating liquids for jacketing on reactors or heat exchangers, cooking or sterilizing in-line.

When used with a temperature probe and a steam control valve, the eductor will result in an almost instant temperature adjustment. The lag time of the temperature probe and valve will affect the performance of the system lag more than the eductor itself.

General Rules for Selecting Eductors

- Is the steam pressure lower than the liquid pressure? If the answer is yes, choose one of the following eductors: MLE, MLH. These units will function pulling a low pressure steam into a higher pressure liquid stream.

- If the unit is to be used on a recirculating stream, consider the ULJ unit.

- If the steam pressure is higher than the liquid, consider the ULJ.

- If low pressure drop is allowed on the liquid stream, consider the ULJ.