Slurry Eductors |

An excellent replacement for conventional auger or belt conveyors, eductors offer the advantage of ambient pressure solids introduction of vacuum conveying systems and the discharge capabilities of positive pressure conveying systems. These jet pumps use the tendency of a moving stream of air to shear towards a boundary surface. This is known as the Coanda effect. This shearing effect and the geometry of the jet pump causes entrainment of ambient air and solid material in the front of the jet pump. This entrained air and solid material are then transported down a length of pipe.

Unlike vacuum based systems, the Model SG is a true pump the entrains the material at the source and pushes the air/solids mixture through the system. Working in a closed piping system, there is little opportunity for material loss or external contamination. In general, piping and feed requirements that provide good material flow in an existing vacuum or blower system are applicable to the SG. The material feed is at ambient pressure, thus eliminating the need for rotary valves and/or blow tanks. In certain applications, these units used alone can replace the function of some dual vacuum/positive pressure systems.

Potential applications include: moving bulk solids & powders and particle collection/evacuation. Industries that could benefit from using this method of transporting dry solid material include: feed & grain operations, plastic/resin manufacturers & users, particulate chemical manufacturers & users, mining operations, foundries, sugar/salt mills, fertilizer handling operations and general manufacturing. |

| Slurry Eductors |

For handling hard-to-wet powders, often used as thickeners and stabilizers in emulsions and suspensions, our Models SL, ML, HL and ULJ offer an extremely good solution. They provide almost instantaneous hydration and avoid clumps and 'fish-eyes'. They have been used with polymers, such as Carbopol, and foods such as guar gum and carageenan. The addition of powdered products into tanks is often left as a manual operation even in otherwise highly automated plants. Scoops, buckets, bags - and their accompanying dust and spillage - still often surround tanks and mixers. |

| Previous Page |

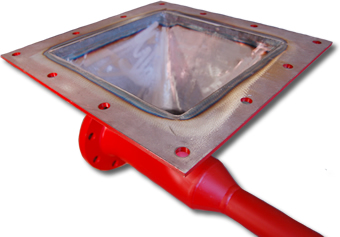

Jet pumps may also be used to transport dry solids using a gas (e.g. air) as its motive source. Jacoby Tarbox Model SG jet pump can be used to convey powders and bulk solids via dilute phase through a closed piping system.

Jet pumps may also be used to transport dry solids using a gas (e.g. air) as its motive source. Jacoby Tarbox Model SG jet pump can be used to convey powders and bulk solids via dilute phase through a closed piping system.  Slurry Eductors are used to introduce solids into liquids with no moving parts. They are an ideal way to continuously produce solutions or well blended slurries and are commonly used in chemical, food, power, pharmaceutical, and waste water applications. As with Fox solids conveying eductors, they have been installed with an enormously broad range of products. Applications of Fox slurry eductors range from adding a few pounds per hour of whey into a milk stream to transporting over 100 tons/hr of flyash at a power plant.

Slurry Eductors are used to introduce solids into liquids with no moving parts. They are an ideal way to continuously produce solutions or well blended slurries and are commonly used in chemical, food, power, pharmaceutical, and waste water applications. As with Fox solids conveying eductors, they have been installed with an enormously broad range of products. Applications of Fox slurry eductors range from adding a few pounds per hour of whey into a milk stream to transporting over 100 tons/hr of flyash at a power plant.